Retour au début 10 Fabricants de cisaillements métalliques hydrauliques robustes dans le monde entier

Dans un environnement où la précision, Disponibilité, et les coûts prévisibles déterminent la compétitivité, la bonne cisaille métallique hydraulique lourde transforme la matière première en reproductibilité, pièces prêtes à souder avec un minimum de déchets. Beyond a clean cut, manufacturers care about dimensional integrity, cycle time, and how well the machine fits into an automated workflow. Choosing the right Heavy Duty Hydraulic Metal Shear is therefore both a technical and strategic decision.

Retour au début 10 Fabricants de cisaillements métalliques hydrauliques robustes dans le monde entier

The strongest names blend engineering depth with practical support. Their machines aren't just powerful; they're built to stay in tolerance, run long hours, and be simple to maintain.

1. AMADA

Origin: Japan

Founded: 1946

Site internet: www.amada.co.jp

AMADA is known for process integration and stable automation. Its Heavy Duty Hydraulic Metal Shear platforms aim for fast setup and steady control, enabling high-volume lines to hit tight takt times while preserving edge quality and squareness.

2. Baykal

Origin: Turquie

Founded: 1957

Site internet: www.baykal.com.tr

Baykal is often shortlisted for balanced value. With configurations spanning light to heavy-duty and broad customization, Baykal appeals to shops that need dependable performance and straightforward support without overspending.

3. Durma

Origin: Turquie

Founded: 1956

Site internet: www.durma.com.tr

Durma emphasizes durable construction and easy upkeep. Consistent pressure control and rugged mechanics help crews run long shifts, delivering dimensional accuracy under demanding workloads.

Gasparini

Origin: Italy

Founded: 1969

Site internet: www.gasparini.com

For over half a century, Gasparini has blended Italian engineering excellence with industrial innovation to create precision metalworking solutions. Specializing in hydraulic shearing and bending technology, our Heavy Duty Hydraulic Metal Shears are engineered for uncompromising performance, durabilité, and intelligent operation. Trusted by leading manufacturers across automotive, aérospatial, and heavy equipment sectors worldwide, Gasparini delivers the precision and reliability that modern industry demands.

5. LVD

Origin: Belgium

Founded: 1952

Site internet: www.lvdgroup.com

LVD combines advanced controls with refined hydraulics. Intuitive interfaces shorten training, while energy-aware designs help reduce operating costs across varied sheet materials and thicknesses.

6. ADIRA

Origin: Portugal

Founded: 1986

Site internet: www.adira.pt

ADIRA pairs innovation with tight quality assurance. From compact shop-floor units to large production systems, its Heavy Duty Hydraulic Metal Shear range focuses on stable accuracy and components designed for continuous duty.

7. Boschert

Origin: Allemagne

Founded: 1963

Site internet: www.boschert.com

Boschert brings German-style engineering discipline to shearing: rigid frames, clean hydraulic layouts, and effective hold-downs that reduce vibration and enable consistent throughput on larger plates.

8. Yawei

Origin: CHINA

Founded: 1994

Site internet: www.yawei.com.cn

Yawei leverages sustained technology investment for precise positioning and repeatability. Its Heavy Duty Hydraulic Metal Shear lines integrate well with data-driven production, supporting demanding industrial workloads.

9. SafanDarley

Origin: UK

Founded: 1949

Site internet: www.safandarley.com

SafanDarley, headquartered in the Netherlands, is tied to automation and energy-efficient technology. Smart controls and ergonomic machine design raise productivity while keeping total cost of ownership in check.

10. Cincinnati

Origin: USA

Founded: 1890

Site internet: www.cincinnatir.com

Cincinnati draws on a long machinery legacy for heavy-duty shearing. Rigid frames, accurate backgauges, and dependable hydraulics deliver consistent results over extended service lives, a match for plants that prioritize durability.

Why Heavy Duty Hydraulic Metal Shears Matter

Shearing quality sets the tone for everything downstream. Poor cuts add burr, taper, and dimensional drift, raising rework and scrap and slowing the line. A Heavy Duty Hydraulic Metal Shear generates steady force through the stroke, maintains squareness, and limits deformation - especially critical on thin stainless or aluminum. Pair that with a rigid frame, precise backgauge, and stable hold-downs, and you get consistent throughput less dependent on operator finesse.

Common bottlenecks persist in many shops. Blade gap changes can be time-consuming; rake angle must be tuned for different materials; long sheets need support to avoid sag and twist. Energy use and hydraulic leakage add to total cost. New-generation shears tackle these issues with closed-loop hydraulic control, leak-resistant circuits, optimized structures validated by FEA, and better ergonomics. The net effect: reproducible cut quality, Moins d’arrêts, and safer operation shift after shift.

How to Specify a Heavy Duty Hydraulic Metal Shear

Start with the application and work backward. Define daily performance targets, lifecycle stability, and serviceability before comparing vendors.

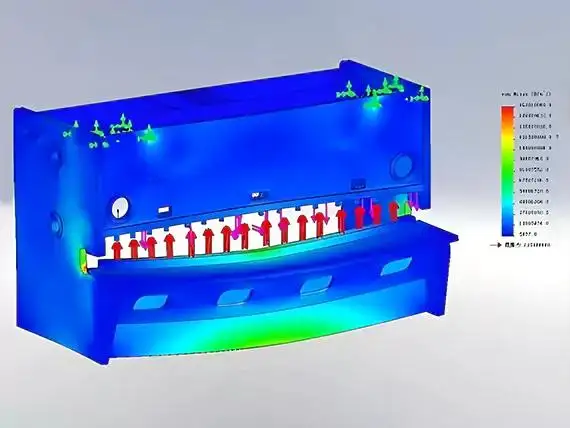

•Rigid, FEA-Validated Frame: Limits deflection under load to protect angle, straightness, and long-term accuracy, especially on wide plates and thicker stock.

•High-Integrity Hydraulics: Stable pressure, Réponse rapide, and low leakage produce consistent cutting force and shorter cycles while preserving components.

•CNC/NC Control: Automated management of backgauge, Écartement des lames, and rake angle reduces setup time and operator variability, improving repeatability.

•Blade Metallurgy: Wear-resistant tool steels (Par exemple, H13) extend edge life and help maintain cut quality during heavy-duty use.

•Sheet Support and Hold-Downs: Front supports, robust hold-downs, and anti-deformation features keep long plates flat and stable for precise positioning.

•Safety and Service: Compliant guarding, Diagnostic clair, and responsive service networks reduce downtime and risk over the machine's life.

•Automation Readiness: Loading, feeding, and integration options enable higher throughput and labor efficiency without sacrificing accuracy.

•A practical rule of thumb: for thin material, a guillotine shear with near-zero, CNC-controlled rake angle minimizes twist and deformation; for thicker plate, adjustable angle reduces cutting force and energy draw. Check backgauge stroke and repeatability for nested programs, and confirm the controller's usability so operators can move quickly from job to job.

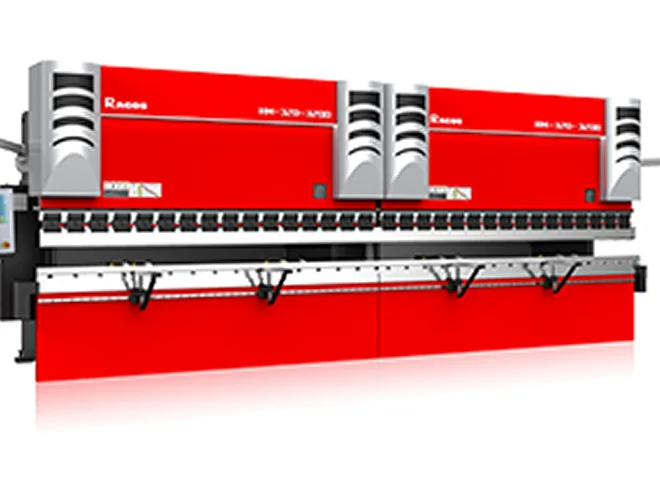

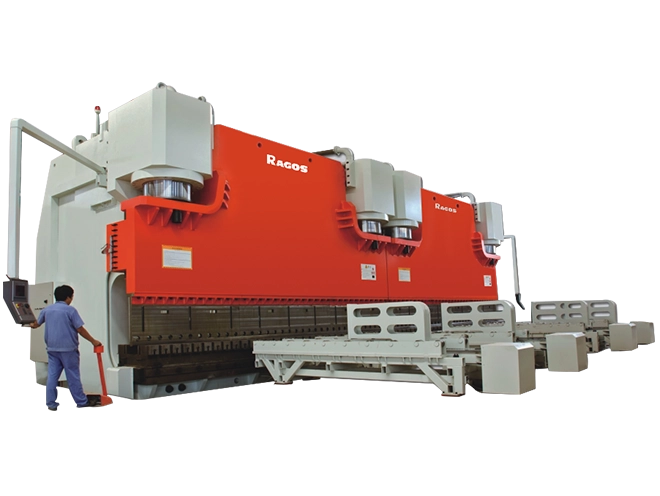

Spotlight on JS RAGOS Heavy Duty Hydraulic Metal Shear Solutions

Jiangsu RAGOS (JS RAGOS), established in 2011 as the manufacturing base of RAGOS Group in Jiangsu, Chine, delivers metalworking machinery and automation to global customers. The portfolio spans press brakes, Machines à laminer des plaques, Machines à tondre, Automatisation du soudage, cellules de flexion robotisées, and press brake automation lines. Avec un chiffre d’affaires annuel de USD 50 million, JS RAGOS pairs engineering depth with application-led support.

Le JS RAGOS guillotine shearing line is engineered for precise, efficient plate cutting. CNC control governs blade gap and shearing angle by material and thickness, automating settings that operators often struggle to repeat. The largest configuration cuts plate up to 55 mm, addressing heavy-duty tasks without compromising edge quality. For higher throughput, optional automatic loading and feeding systems integrate to create continuous flow from stock to finished blanks.

Structural integrity is validated before production. Frames undergo Finite Element Analysis to map stress, déformation, and cutting forces. This discipline helps protect cut accuracy under high-duty cycles and extends service life.

Control architecture is tailored to the job. Users can choose simple NC for straightforward runs or advanced CNC for complex programs and frequent changeovers. Automated backgauge positioning, Écartement des lames, and rake angle reduce setup, stabilize results, and support repeatability across shifts.

Hydraulic performance draws on components from Rexroth in Germany, delivering steady cutting force under load, smooth motion profiles, et longue durée de vie. Precision hydraulic control supports energy efficiency by limiting heat and avoiding pressure overshoot.

Drive technology reinforces accuracy. Siemens motors are standard for reliable torque and longevity. For tighter motion control and lower energy use, an optional servo drive refines positioning and speed profiles in demanding applications.

Process control extends to automatic angle optimization. The system sets the best rake for each material and thickness, reducing deformation on thin sheets and cutting force on thicker plates. The payoff is consistent edges and reduced energy consumption without manual trial-and-error.

Sheet handling receives deliberate attention. Front supports stabilize large or long plates and aid alignment. H13 tool steel blades offer wear resistance and a durable cutting edge. A CNC-controlled backgauge secures consistent positioning. An optional anti-deformation support device holds long sheets after cutting to prevent bending and maintain flatness.

✅ Key capabilities at a glance

•FEA-optimized frame for strength, raideur, and accuracy retention over time

•CNC/NC control of backgauge, Écartement des lames, and rake angle for fast, repeatable setup

•Rexroth hydraulic system for stable force, smooth operation, et l’efficacité énergétique

•Siemens motor standard; optional servo drive for refined control and energy savings

•Automatic angle control to reduce thin-sheet deformation and cutting force on thick plate

•Front sheet support and optional anti-deformation device for long plates and large formats

•H13 blades for longevity and consistent edge quality

•Optional loading and feeding systems to enable higher automation and throughput

Conclusion

Investing in a Heavy Duty Hydraulic Metal Shear shapes cut quality, Débit, et coût du cycle de vie. The ten manufacturers above combine control, hydraulics, and service capability to meet industrial demands. JS RAGOS adds FEA-led structures, intelligent CNC automation, high-grade hydraulics, and robust sheet support to sustain accuracy under heavy-duty conditions. With a clear specification and the right partner, plants can reduce scrap, Raccourci en configuration, and achieve reliable, high-precision cutting at scale - turning the Heavy Duty Hydraulic Metal Shear from a single machine into a cornerstone of profitable plate processing.