مكابح CNC للضغط بالجملة | دليل الصيانة والتشغيل: نصائح محترفة

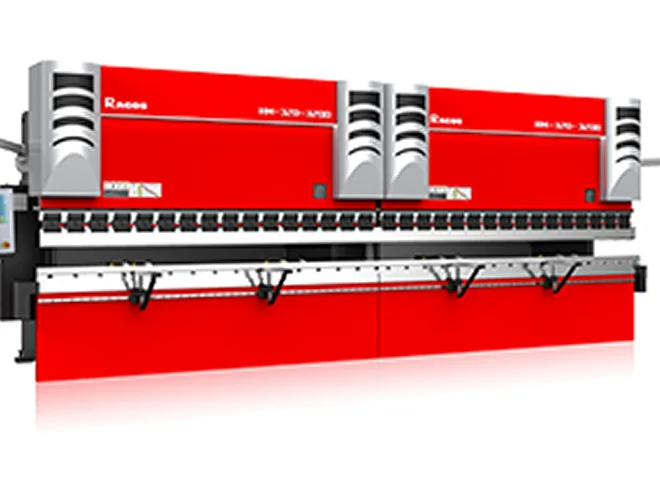

تنجح برامج CNC Press Brake Wholesale عندما تكون جودة الإخراج ثابتة, استهلاك الطاقة مسؤول, والسلامة متجذرة في كل دورة- المبادئ التي يبنيها JS RAGOS في كل نظام.

Maintenance and Operation Priorities for CNC Press Brake Wholesale

In wholesale and contract environments, the press brake often defines throughput. Overall Equipment Effectiveness hinges on stable processes: first-pass yield must be high, cycle time predictable, and energy cost per bend under control. Reactive maintenance and ad-hoc operation erode margins by causing angle drift, إعادة العمل, and unplanned stops. A disciplined approach transforms the same equipment into a dependable work center that holds tolerance across shifts and materials.

JS RAGOS treats maintenance and operation as a closed loop. Hydraulic stability and controlled temperature protect components and preserve repeatability. Tooling integrity and angle verification eliminate uncertainty in the first part and reduce re-bends later in the run. Automation trims handling variability and shortens changeovers. This systems view aligns with the demands of CNC Press Brake Wholesale buyers who require long-run repeatability, التتبع, and safe operation without adding labor.

Three persistent pressures dominate modern bending operations. Energy is wasted when conventional hydraulic systems draw power at idle and heat the shop environment. Angle consistency varies with alloy, سمك, and grain, making springback unpredictable. Setup and changeover consume valuable time when operators juggle tool swaps, manual feeding, and verification steps. Addressing these issues at the platform level - drive, measurement, tooling flexibility, feeding, and protection - creates a process that is easier to maintain and faster to run, day after day.

Pro Tips from JS RAGOS: Keep Accuracy High and Downtime Low

A concise set of practices helps maintain accuracy, extend service life, and stabilize OEE without slowing production. Use the following measures to make best practice routine.

•Keep Fluids And Motors In Range: Heat and contamination cut hydraulic life. Industrial cooling holds oil and servo temperatures steady, sustaining precise axis control under high duty cycles.

•Check Tools; Clean Contact Points: Inspect for wear, burrs, or damage; wipe bed and backgauge. Clean interfaces reduce marking and improve angle repeatability.

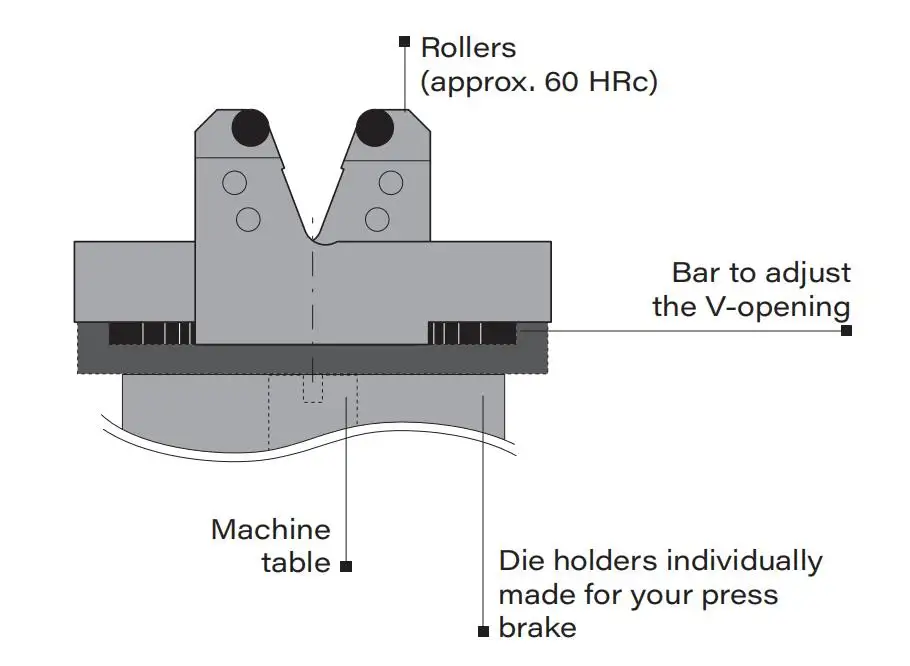

•Size The V-Opening Correctly: The right V reduces tonnage and enhances edge quality. Vario dies support multiple V settings along the bed for rapid changeover.

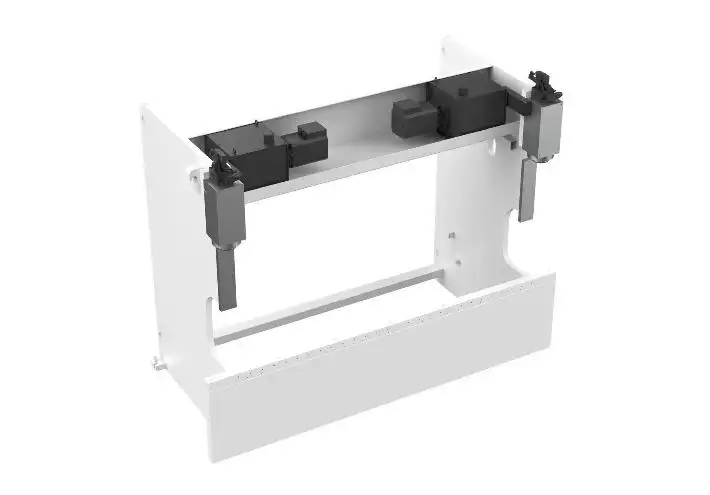

•Crown Before First Article: Apply crowning to counter deflection so long parts keep a constant angle, lowering trial bends.

•Measure The First Bend, Then Correct: Laser Check projects a beam onto the sheet; a camera computes the actual angle and compensates springback automatically. Accuracy exceeding ±0.1° is achieved after a single bend, cutting rework.

•Automate Feeding For Alignment: CNC plate feeding keeps sheets square to the backgauge and smooths cycle time. Conveyor or roller systems integrate with Delem, ذلك, سيبيليك, or STEP controllers for high-volume stability.

•Dynamic Guarding: The DSP laser light curtain follows the punch, forming a mobile protective area; breaches halt motion on the spot - protection without productivity loss.

•Digital First: Use 2D/3D CNC programming backed by full 3D simulation to validate bend order, تحركات القياس الخلفي, and interference paths. This protects tooling and reduces setup time for multi-step parts.

A short daily checklist reinforces control:

•Lubricate as specified; clear chips and dust from guides and scales.

•Verify backgauge movement and zero points before the first job.

•Run a first-piece angle check per part family.

•Investigate alarms promptly; never bypass safety interlocks.

The JS RAGOS Platform: Turning Best Practice into Standard Work

JS RAGOS integrates energy-saving hydraulics, real-time angle measurement, adjustable dies, تغذية CNC, industrial cooling, and optical protection to convert good intentions into consistent outcomes. The result for CNC Press Brake Wholesale buyers is a platform that is simpler to maintain and easier to operate at scale.

Energy and Thermal Stability

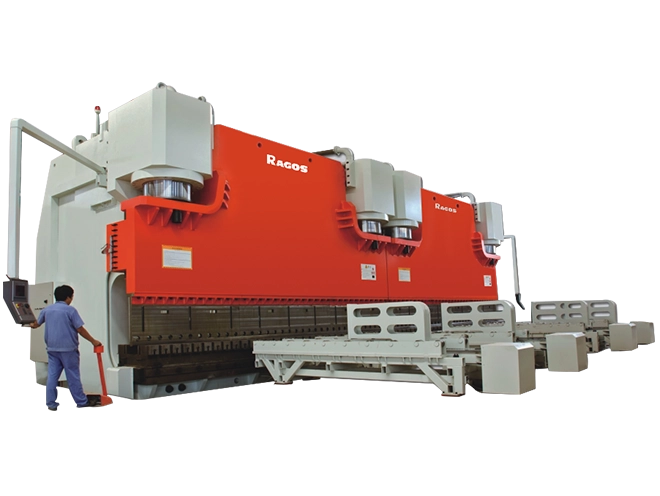

نائب الرئيس الديمقراطي (مضخة الصمام المزدوج) system is engineered for heavy-duty brakes and large parts. Relative to conventional hydraulic drivetrains, DSVP delivers ~60 - 70% energy savings alongside fast response, low noise, and stable pressure. Dual-servo control reduces idle losses, keeps heat in check, and lessens mechanical stress. Fewer hydraulic components translate to lower failure rates and easier service. By stabilizing hydraulic oil and servo motor temperatures, our industrial cooling unit backs up the drive, preventing seal and valve fatigue and sustaining accuracy across long shifts and heat waves. The mix of energy savings and thermal discipline reduces cost-per-bend and extends machine longevity.

Precision and Repeatability

Repeatability starts with measurement and compensation at the point of bend. The Laser Check system - developed with Data-M and Vision Components - projects a laser onto the sheet while a camera determines the resulting angle. The control compensates springback and optimizes force, achieving accuracy exceeding ±0.1° after a single stroke regardless of common variations in grade or thickness. Introducing a tunable upward camber in the bed, the crowning table counteracts deflection for consistent angles on extended bends. Measured feedback plus geometric compensation reduces try-and-adjust cycles, safeguards tooling, and compresses SPC variability across lots. This level of control supports CNC Press Brake Wholesale requirements for multi-site, multi-shift consistency.

اتمته, Changeover, and Operator Safety

Throughput and quality improve when material handling and hazard control are built into the system. The CNC plate feeding device automatically positions sheets in the bending zone via conveyor or rollers, reducing manual handling and aligning each part square to the backgauge. The feeder connects with leading controls - جزئيا, ذلك, سيبيليك, الخطوة- for synchronized flow in high-volume operations.

For flexible production, the Vario adjustable die system is segmented in 1000 mm modules and scales from 1 حتى 12 m beds. Each segment can be set to a different V-opening using a pneumatic gear system at 6 بار, positioned by scale or CNC signal. Shifting from minimum to maximum V takes about five seconds, with an acoustic signal confirming position. Hardened rollers inside the die reduce bending force by 25 - 30%, lowering tonnage demand, machine stress, and energy draw - especially valuable on mixed part queues and thinner materials.

Operator safety is enforced with a DSP laser light curtain that creates a protection zone under the upper tool. If fingers or any object enter this moving zone, the system halts motion immediately. The result is a safer workplace that does not slow production or compromise setup visibility.

Tooling and Control Customization

Control architecture and tooling quality define setup speed and bend fidelity. JS RAGOS offers customizable CNC control configurations from 4-axis through 6-axis and 8-axis to match your production profile - single-hit work, complex multi-step sequences, or fully automated cells. Advanced 2D and 3D programming with comprehensive 3D simulation shortens commissioning, prevents collisions, and standardizes best practice across operators.

Tooling is manufactured from premium 42CrMo alloy steel and precisely heat-treated for durability and dimensional stability. Segmentation services produce manageable lengths that speed installation and changeover. To preserve compatibility and simplify inventory, we build tooling to interface with Wila, أمادا, and other major systems. In a CNC Press Brake Wholesale context, this approach reduces SKU complexity, supports uniform training, and sustains bend quality across facilities.

خطوتك التالية

If your roadmap calls for lower energy per part, fewer re-bends, safer workcells, and faster changeovers, JS RAGOS can help you reach those goals with measurable gains. Our platform saves up to 70% طاقة, maintains ±0.1° bending accuracy, integrates DSP laser protection and Laser Check measurement, supports CNC plate feeding, and adds flexibility with Vario adjustable dies, industrial cooling, تتويج, customizable controls, and durable 42CrMo tooling. Engage JS RAGOS for an application review, live demonstration, or tailored quotation. We will map your part mix, cycle times, and staffing model to a scalable configuration that lifts throughput and quality - built for the standards of CNC Press Brake Wholesale.