All'interno del freno pressante CNC 4000mm | Come funziona

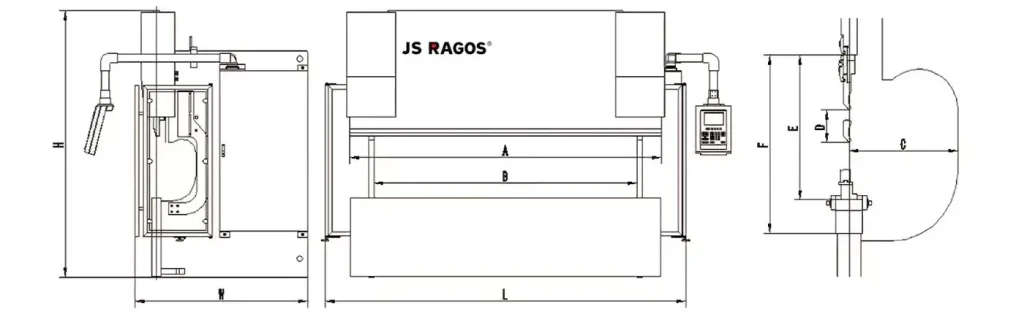

Il freno a pressione CNC 4000mm è un sistema di precisione per la piegatura della lamiera. Utilizza il controllo computerizzato per guidare la RAM, Utensili, e scartamento di arretramento. Forma angoli accurati su pezzi lunghi. It supports complex parts and repeatable production. It integrates hydraulic or servo control for stability. It manages bend sequences through programmed steps. It reduces variation and improves throughput. How does it achieve such consistency and speed? The answer lies within its control logic, Sensori, and motion strategy. The following sections examine the machine and reveal its method.

All'interno del freno pressante CNC 4000mm

- Punch, Le, and Controlled Motion

At its core, Le 4000 mm CNC press brake bends metal by driving a punch into a die. The CNC system aligns ram motion with backgauge positions to lock the datum. A controlled hydraulic or servo force profile shapes the bend, which is defined by punch penetration into the die opening.Tool geometry and material properties influence the final result. This approach supports both air bending and bottoming, so teams can reach different radii and angles with confidence.

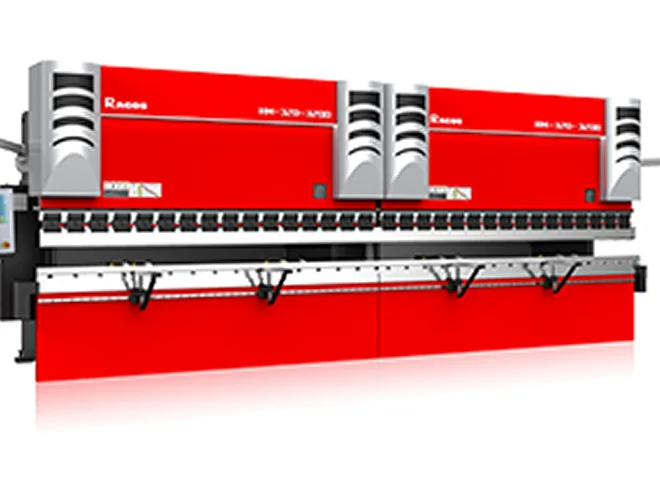

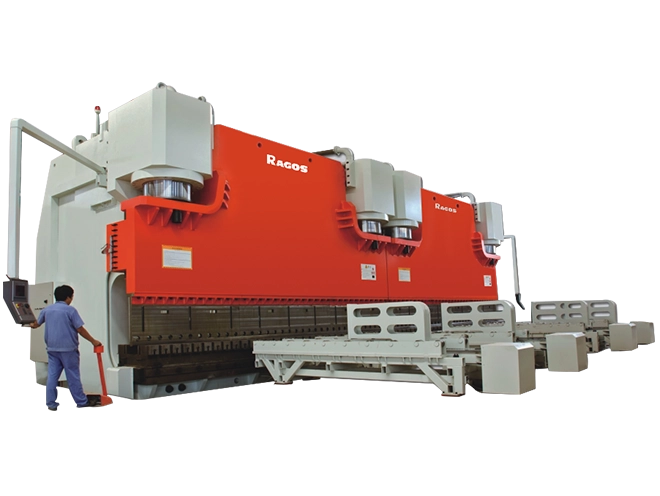

The JS RAGOS approach adds stability along long parts. The CNC Press Brake 4000mm uses a rigid frame and precision guides to limit deflection across the working length. Load distribution is balanced across the bed to protect angle uniformity from end to end.When forming wide panels or tall enclosures, this stiffness matters. It prevents angle drift and reduces the need for touch-up. With the right punch radius and die V-width, operators can repeat results shift after shift.

- Backgauges, Sequencing, and Springback

Accuracy is more than angle control. Flange length consistency is critical for assemblies.Servo-driven backgauges position the sheet against fingers that act as stops. The closer the stop to the tools, the shorter the flange. On complex parts, the CNC repositions the backgauge after each bend to the next programmed distance. This keeps the stack-up of dimensions within tolerance and reduces manual handling.

Springback is always present.It depends on thickness, grade, and radius. The CNC Press Brake 4000mm compensates by applying over-bend angles or dwell at the bottom of stroke. Penetration depth is adjusted so the released angle matches the drawing. JS RAGOS supports both on-machine programming and offline CAD/CAM. Complete bend sequences can be simulated to verify clearance and to confirm the planned radii before the first cycle.

Capienza, Utensili, And Design For Accuracy

- Force Planning and Key Benchmarks

Capacity defines what can be formed. The maximum force and the working length determine which thickness, bend length, angolo, and radius combinations are feasible. With the CNC Press Brake 4000mm, production teams can address large parts with up to 4,000 mm bend length and up to 250 tonnes of available force.Force demand rises with thickness, bend length, and external angle. It falls as the die opening and bend radius increase.Planning around these rules minimizes trial bends and scrap.

The following examples help assess feasibility for a 90° bend in mild steel:

•1.5 mm thickness at 3,000 mm bend length with 2 mm inner radius typically needs about 45 tonnes.

•5.0 mm thickness at 3,000 mm bend length with 4 mm inner radius typically needs about 150 tonnes.

These benchmarks support early decisions on die selection, punch radius, and part nesting. By aligning material, geometry, and force capacity in advance, teams reduce line interruptions and protect takt time. Tooling Choices And Clearance Strategy

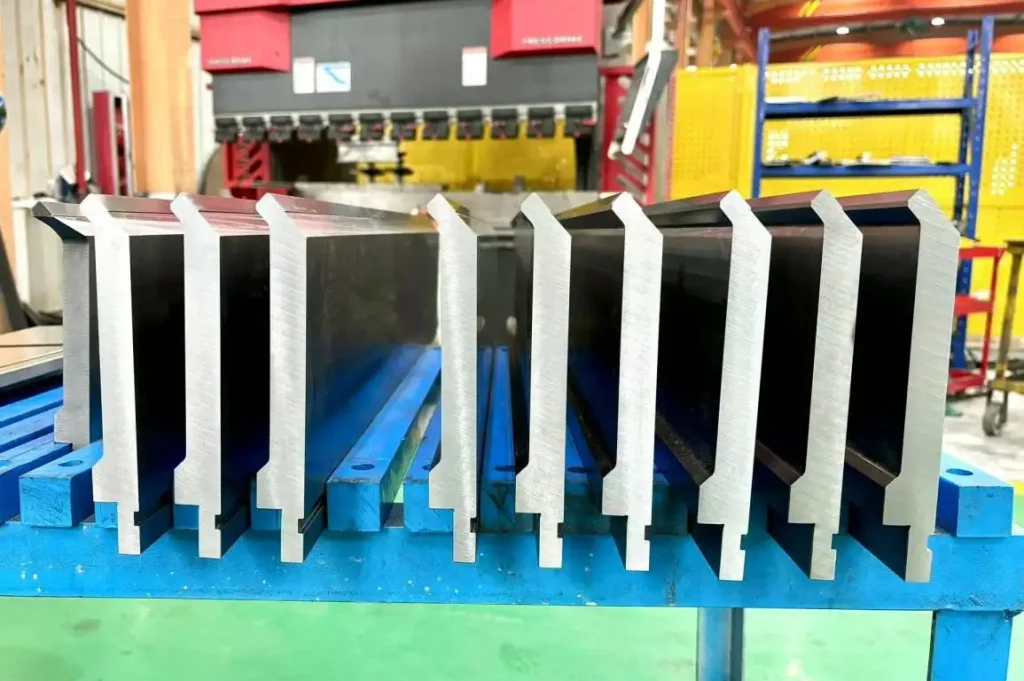

Tooling sets the achievable radius and the surface quality. Thicker materials often call for a larger punch tip radius and a wider V-width. For sharp angles or small radii, over-bending tools with more acute included angles can counter elastic recovery. Multi-bend parts introduce another constraint. Without clearance, an existing flange can strike the punch during a later bend.Gooseneck punches solve this by creating space for the formed flange. For extreme cases, extended or suspended clamps elevate the tool body to increase portal clearance, provided the stroke accommodates the overall height.

Tool selection and setup should not slow production. The JS RAGOS control links material grade, Spessore, and target angle to a library of punches and dies. Recommended combinations are presented at the HMI. This shortens changeovers and reduces the risk of incorrect tool choice in high-mix environments. Tool IDs are confirmed by on-screen checklists and optional barcode scanning to ensure the machine and the setup match the program.

Design decisions also shape bending success. Blank development must account for the radius formed on the press brake. Larger radii cut down the developed flat. When the called-out radius conflicts with the die set, assemblies can misalign. At JS RAGOS we front-load radius/tooling alignment so flat patterns stay true and rework is minimized.

From Shop Pain Points to JS RAGOS Advantages

Where Bending Often Fails

Manufacturers face recurring obstacles that waste time and material. The most common issues include:

•Angle drift along long panels due to deflection and uneven load distribution.• Collisions between tools and already formed flanges on multi-bend parts.

•Excessive changeover time when switching materials and geometries.

•Springback underestimation that leads to rework and inconsistent angles.

•Programming bottlenecks on high-mix, low-volume orders.

Each of these problems reduces throughput and increases cost. They also create quality risks that can reach the customer if not controlled.JS RAGOS addresses these challenges with a balanced mechanical design and intelligent control. The CNC Press Brake 4000mm maintains stiffness across the working length for consistent angles. Real-time control of penetration depth and motion profiles maintains stability. Tool libraries and guided setup shorten changeovers. Clearance tools and gooseneck options prevent interference. Offline programming with simulation visualizes the entire sequence before the first part is bent.

Proven Workflow and Call to Action

A disciplined process converts machine capability into stable output. Operators begin with setup by selecting the correct punch and die and by loading the program. The machine verifies backgauge positions and displays a bend map. The operator loads the material and squares it to the backgauge. The ram advances - hydraulic or servo - to produce the angle by precise penetration. Overbend or hold-at-bottom offsets springback. The part is removed for quality verification or subsequent processing. When needed, the CNC indexes to the next bend and moves the backgauge automatically. This reduces manual inputs and improves safety.

Beyond mechanics, support and training matter. JS RAGOS provides standard bend libraries, parameter guidance for common materials, and best-practice templates. These resources help new operators reach first-part success quickly and help experienced teams increase throughput. For plants scaling production, we offer optional automation and integration with upstream laser cutting or punching cells. Data from the press brake can be linked to MES for traceability and OEE analysis.

Call to Action: If your team is seeking tighter angles, Cambi di passaggio più rapidi, and reliable results on long parts, speak with JS RAGOS. The CNC Press Brake 4000mm helps unify tooling strategy, capacity planning, and bend sequencing. Request a consultation, set up a live demo, or ask for a tailored quotation. Our engineering team will review your parts, propose tooling and radii, and support a dependable, efficient bending process.