Какие преимущества качества даёт станок для изгибания панелей с ЧПУ?

CNC Panel Bender Machine переопределяет контроль качества в производстве листового металла, превращая изгиб в предсказуемое, Процесс, основанный на данных.

The QC Pain Points in Bending that Our CNC Panel Bender Machine Solves

- Variability, Rework, and Hidden Cost

Across many bending lines, QC issues share the same root causes: angle drift from springback, inconsistency across operators, tool wear, and frame deflection under load. Variability at the source spawns rework loops, raises scrap, and slows production. Quality teams chase nonconformances over verifying compliance. Every correction adds cost and risk.

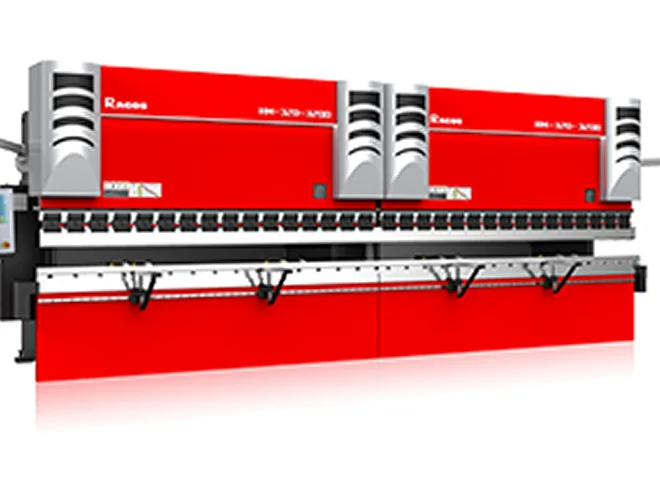

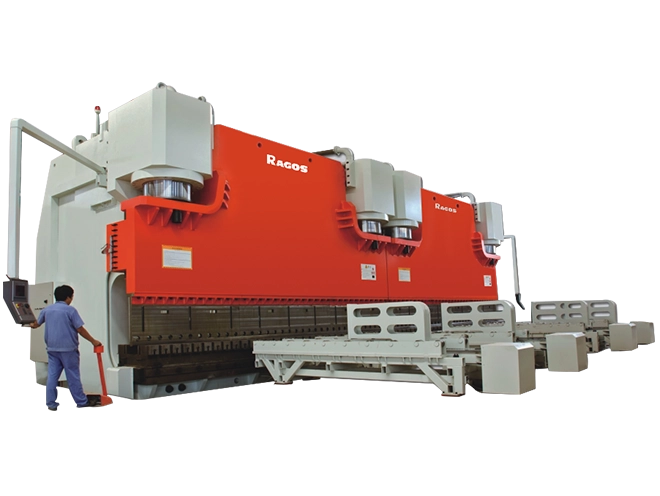

JS RAGOS resolves this by designing-in consistency throughout the bending process.Our CNC Panel Bender Machine stabilizes the mechanical system, controls the motion profile, and measures what matters. The result is tighter tolerances at the first pass. QC moves from end-of-line catching to in-process assurance. This reduces variability and cuts the time between bending and downstream assembly.

- From Manual Skill to Controlled Process

Traditional bending relies heavily on operator experience. Skill is valuable, yet variability remains.Material batches change. Springback shifts with thickness. Setup pressure can alter bend angles.These are common sources of defects.

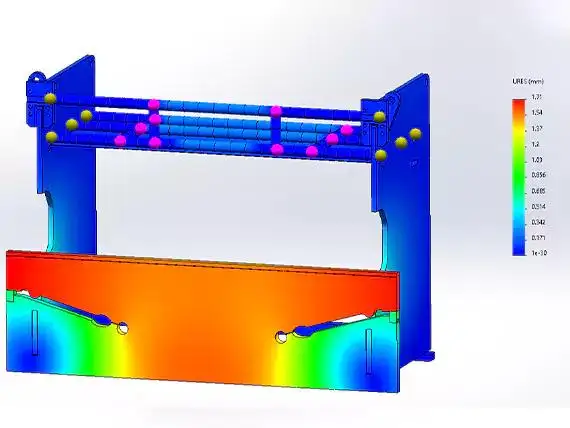

A CNC Panel Bender Machine from JS RAGOS replaces subjective adjustments with verified parameters. Анализ методом конечных элементов (УРОДЛИВЫЙ) optimizes the frame for stiffness and load paths before production, improving structural stability under real conditions. Servo axes deliver repeatable motion. The controller enforces angle targets, dwell timing, and speed profiles with precision. That standardization gives QC reliable data and capacity to scale.

Reliable QC Gains with JS RAGOS CNC Panel Bender Machine

- Точность, Повторяемость, and Angle Stability

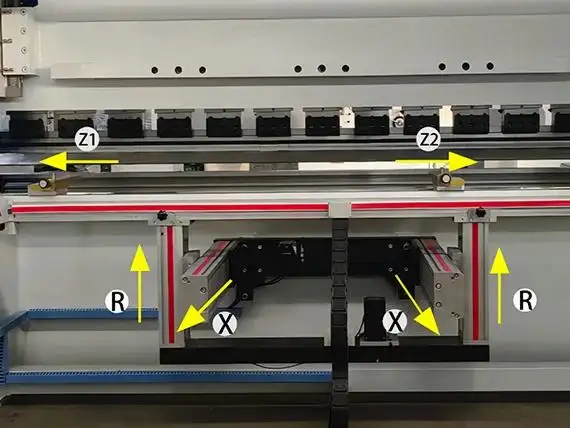

Quality begins with controlled geometry. The CNC Panel Bender Machine holds target angles and positions across long sequences. Micrometric systems uphold repeatable positioning. When paired with advanced verification, angle accuracy is confirmed after the first hit.

Laser-assisted angle measurement, developed with machine vision partners, can achieve angle verification with accuracy exceeding ±0.1°. It compensates for springback and applies force optimally for consistent results. This closes the loop between programmed angle and actual part geometry and reduces the need for multiple trial bends.For panel edges and flanges, this is critical: one bend, verified, then the line flows.

Back gauge and referencing are equally important. Precision linear guides and ball screws enable position accuracy around ±0.03 mm. That precision upstream drives assembly fit later. Tolerance stacking is reduced, and QC sees fewer dimensional outliers in batch reports.

- Stable Process, Safer Workcells, and Traceable Data

Process stability protects quality. JS RAGOS servo motors run efficiently and quietly, вокруг 20 дБ, reducing ambient noise and operator fatigue.Energy consumption drops by 20 - 30% versus conventional motors, which reduces heat and keeps hydraulics and electronics within stable operating windows.A stable environment contributes to stable results.

Safety systems are integrated for consistency and compliance.DSP laser light curtains create a protective zone and stop motion when an obstacle enters. This reduces incidents and unplanned downtime, which can often degrade quality through rushed recoveries.

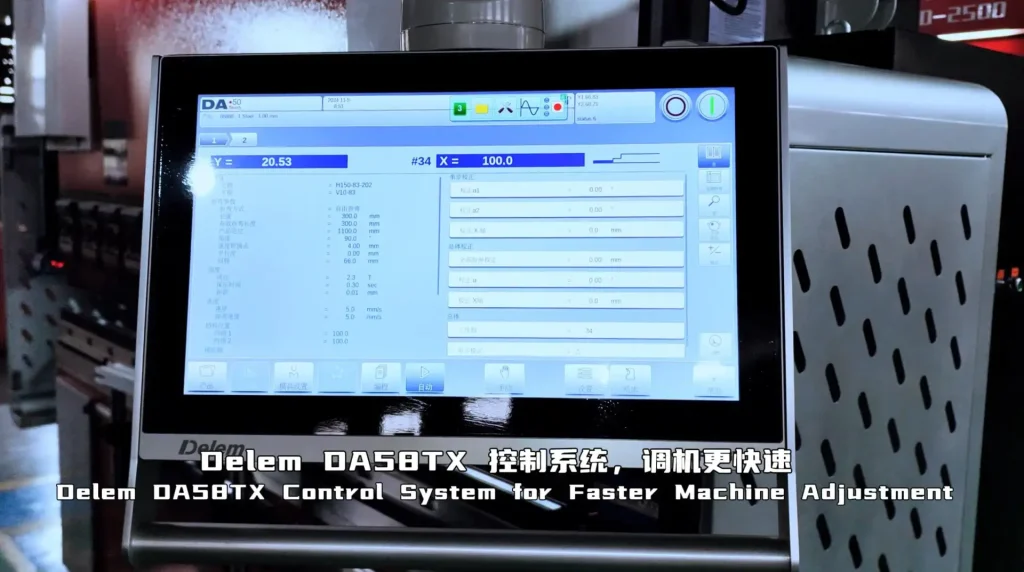

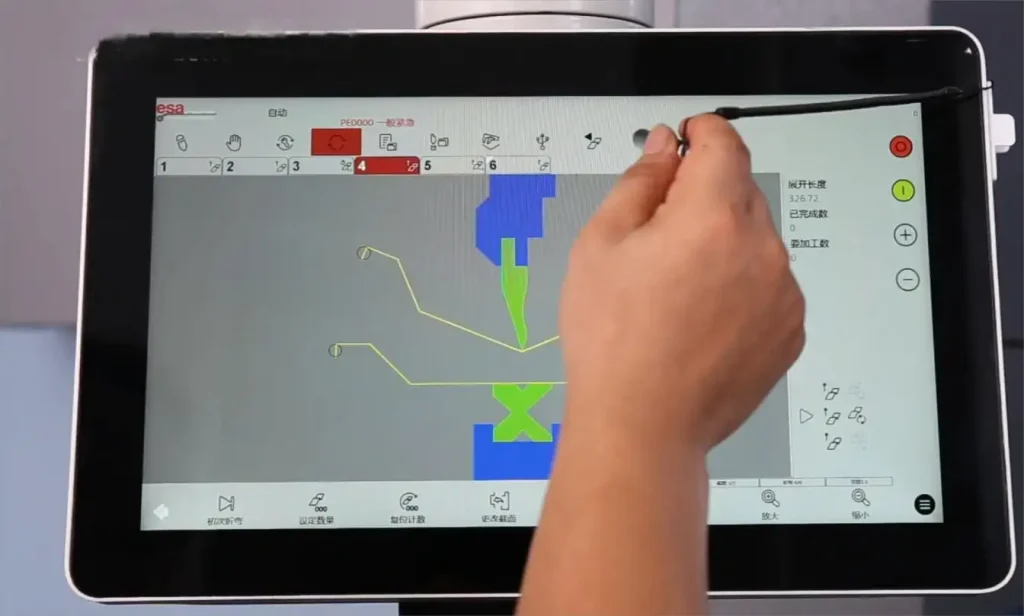

CNC control is the brain of the machine. We support 2D/3D programming and full 3D simulation. Tool paths are validated before production. Cycle parameters are recorded, and part histories are traceable. Collaboration with established CNC control brands ensures dependable performance and precise motion.QC teams gain data that fits Statistical Process Control (SPC) workflows.

Tooling also matters. JS RAGOS supplies high-strength, heat-treated tooling for consistent bending quality. Segmenting options speed changeover, support small batch flexibility, and maintain accuracy across diverse part sets. When tooling remains stable, angles remain stable.

•First-pass yield increases because the machine reaches the correct angle on the first bend.

•Scrap declines as verified angles and precise gauging limit out-of-tolerance parts.

•Setup time drops due to fast programming, симуляция, and quick tool change strategies.

•Inspection time shortens because angle assurance reduces recheck cycles.

•Batch uniformity improves; QC sees tighter distributions and cleaner control charts.

Measured Outcomes and How to Start with JS RAGOS

- QC Metrics You Can Track

Quality gains must be measurable. With a JS RAGOS CNC Panel Bender Machine, the following metrics show improvement early in deployment:

•Angle accuracy: laser-assisted verification with accuracy exceeding ±0.1° reduces rework.

•Positioning precision: gauging with ±0.03 mm supports tighter assembly tolerances.

•First-pass yield: fewer corrective bends; more parts pass initial inspection.

•Scrap rate: as spread tightens, defects drop - double-digit reductions are typical.

•Throughput: конюшня, predictable cycles and quick setup can lift productivity by up to 30%.

•Energy cost: servo-driven savings of 20 - 30% lower energy variability and improve stability.

These metrics roll into SPC dashboards. QC can set control limits, spot drift early, and act fast. Continuous improvement becomes methodical and verifiable.

Ваш следующий шаг

Move decisively toward proactive quality:

•Conduct a targeted QC audit of the bending line to locate variation sources.

•Pilot with our CNC Panel Bender Machine and record baseline KPIs.

•Use 2D/3D programming and simulation to de-risk and speed setups.

•Add laser angle verification and automated data logging for immediate feedback.

•Train operators and QC on parameter stewardship and SPC response plans.

We guide tooling choices, control tuning, and process validation. Axis schemes and compensation models are customized to your use cases. With FEA-optimized structures, power-smart servos, robust safety, and full traceability, JS RAGOS turns bending into a controllable, repeatable process.

Call to Action: Request a live demonstration and a QC benchmarking session with JS RAGOS. See how a CNC Panel Bender Machine can tighten your tolerances, lift first-pass yield, and reduce scrap across your next production run. Our engineers will map the gains to your parts and deliver a plan you can implement.