6 Axe : Axe CNC : Axes de frein à pression expliqués simplement

6 La technologie CNC de frein à pression axiale apporte le contrôle multi-axes à la flexion de précision, Transformer des tâches complexes en flux de travail répétables et efficaces avec moins de configurations et moins de ferraille.

Understanding the Six Axes in A 6 Frein à pression CNC axe

- Positioning Axes: X, R, Z1/Z2

The backgauge is the "positioning intelligence" of a 6 Axe Frein à pression CNC. Four coordinated axes let you place sheet metal precisely for each bend.

• X axis moves the backgauge fingers forward and backward to set flange length. Accurate X control is the foundation of consistent flange dimensions across a run.

• R axis moves the backgauge fingers up and down to support different die openings, staged tooling heights, or reverse flanges. This keeps parts supported while avoiding tooling interference.

Z1/Z2 axes manage the finger positions independently along the machine length. Their autonomy delivers automatic repositioning for multi-bend patterns, asymmetric forms, tapered profiles, and staged configurations - no hand sliding needed. This flexibility is essential for high-mix, low-volume production and for parts that require several bends across different planes.

- Forming Axes: Y1/Y2 And Crowning (V)

The forming accuracy comes from the ram system and table compensation.

• Y1 and Y2 axes control the left and right sides of the ram. Independent servo control keeps the ram parallel under load, compensates for frame deflection, and corrects angle variation along long parts. Precise Y1/Y2 synchronization is the basis of tight angle control.

• Crowning (often called the V axis in control software) actively adjusts the lower table or die bed to compensate for machine and material deflection. Proper crowning maintains consistent angles from end to end, even on long bends, thick plate, or high-tonnage applications.

Ensemble, the six axes let the machine position every bend exactly where it should be (X, R, Z1, Z2) and achieve the target angle consistently (Y1, Y2, V). The result is stable processes, shorter setup times, and predictable quality across shifts.

How to Align a 6 Axis CNC Press Brake with Your Specifications

Analyze bend complexity and tolerance thresholds. For parts with many bend lines, offsets, or asymmetry, select a 6 axis CNC press brake with X, R, Z1, Z2, Y1, Y2, and programmable crowning to shorten setup and reduce first-article scrap. Thin stainless and aluminum benefit from precise backgauge travel and smooth ram control; thick mild steel benefits from a rigid frame and angle-control systems to ensure repeatable angles.

Common production pain points that six-axis capability addresses include:

• Frequent manual adjustment of backgauge fingers between bends

• Inconsistent angles along the length due to deflection and springback

• Excessive first-article scrap in high-mix, low-volume jobs

• Skill-dependent results that vary by operator and shift

• Long setup times caused by multiple tool heights and staged stations

- Logiciel, Sécurité, And Uptime Considerations

Beyond axes, the control platform, sécurité, and mechanical design determine throughput and stability. A modern CNC interface should support 2D/3D programming, automatic bend sequencing, Contrôles de collision, and angle correction. Fast auto-tuning of Y1/Y2 and simple crowning workflows reduce trial bends. Optical guarding allows close-in protection without slowing cycles.

Look for quantifiable performance indicators. As a benchmark, ±0.03 mm positioning on the backgauge and ram feedback with dual scales provide the repeatability needed for tight flanges and consistent angles. Mouvement à grande vitesse sur X, R, and Z axes accelerates staging moves between bends, reducing non-cut time. Thin-sheet support systems prevent small parts from tipping and keep surface finishes clean.

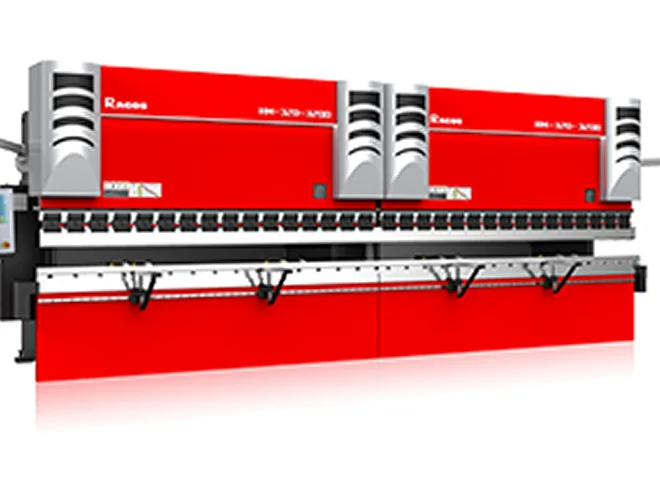

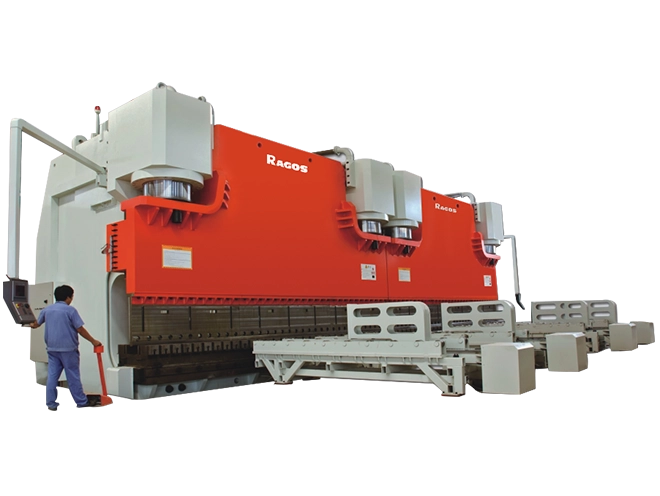

Électrique 6 Axis CNC Press Brake Example and Why It Matters

- Accuracy And Control that Reduce Rework

Un electric 6 Axe Frein à pression CNC centered on a high-strength welded frame and a modern CNC, such as the Delem DA66s, brings machine capability and operator interface together. Dual grating rulers on the ram deliver closed-loop feedback with ±0.03 mm positioning accuracy, stabilizing angles across long bends and mixed materials. With programmable crowning, the machine compensates dynamically for load and material variation, so angle consistency is maintained from the first piece.

On the backgauge, precision motion elements - vis à billes, Guidages linéaires, et courroies de précision- create smooth, repeatable moves on X, R, Z1, and Z2. High-speed traverses shorten staging moves, so the operator spends less time waiting and more time forming. Micrometric double-stop fingers allow fine trimming of flange lengths when chasing tight drawings. A thin-sheet support system (SPA) rated at 30 kg per support holds light parts level and prevents "dive" under the ram, protecting surface finishes and minimizing regrips.

- Configurations plus rapides, Safer Operation, Better Results

Setup time is a major cost driver. Features that shorten tooling and program changeovers pay back quickly:

• Amada-style quick clamps enable rapid punch and die changes, reducing idle time between jobs.

• A modular backgauge design scales from 4 à 6 Axes, aligning investment with current needs while keeping a path for future complexity.

• Optical guarding, such as Lazer Safe IRIS, protects operators with minimal impact on approach speeds, balancing safety and throughput.

The combination of these elements turns six-axis capability into measurable outcomes. Shorter first-article approval, fewer re-bends, and lower scrap reduce cost per part. Consistent positioning and angle control reduce downstream fit-up issues in welding and assembly. Faster staging and safer operation stabilize cycle times and support predictable scheduling.

Call to Action

Before you decide on a 6 Axe Frein à pression CNC, get a tailored application review. Share your geometry and tolerance targets, and we'll recommend axes, outillage, and a data-backed cycle time estimate. Book a live demo to see ±0.03 mm positioning, high-speed X/R/Z movements, and Delem DA66s workflows in action. Prefer to compare offline? Download the specification sheet and a sample program package to review backgauge strategies for your parts.

By aligning the six axes - X, R, Z1/Z2, Y1/Y2, and crowning - with your part mix and tolerances, and by choosing the right control, sécurité, and tooling ecosystem, you can turn bending into a controlled, Processus piloté par les données. A well-specified electric 6 axis CNC press brake delivers the repeatability, setup efficiency, and safety modern fabrication demands.